Hydro excavation uses high-pressure water and vacuum to safely expose underground utilities, ideal for sensitive or congested areas. Mechanical digging uses excavators for faster, bulk soil removal on open sites. Choosing depends on site risks, access, and compliance needs.

Choosing between hydro excavation and mechanical digging isn’t just about equipment; it’s about matching the right method to your site’s safety requirements, subsurface conditions, and compliance demands.

Hydro excavation offers pinpoint accuracy using high-pressure water and vacuum, making it ideal near live utilities or in sensitive environments. Mechanical digging, on the other hand, excels in open areas where speed, volume, and cost efficiency matter most.

Across NSW, we’ve used both methods, sometimes on the same project, to balance precision with productivity. In this guide, we break down the key differences, real-world use cases, and when a hybrid excavation plan delivers the safest and most efficient results.

If you’re planning a site dig, trench, or test pit, this will help you make an informed decision before machines ever touch the ground.

What Is Hydro Excavation?

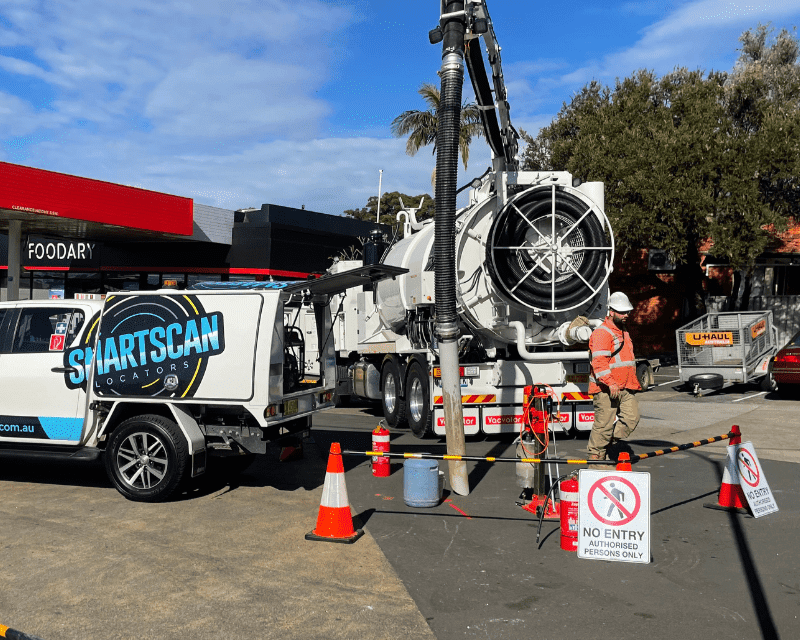

Hydro excavation, also known as non-destructive digging (NDD), is a method that uses high-pressure water and a powerful vacuum system to break up and remove soil. It’s typically performed using specialized vacuum trucks and is widely used in projects where underground services or sensitive environments are present.

This technique allows our team to precisely expose underground assets, like telecommunications, sewer, water, gas, or fibre, without damaging them. It’s especially useful on congested sites, along active roadways, or in situations requiring clean, contained material removal. You’ll often see it used in potholing, drill mud removal, and GSW cartage.

Learn more about our vacuum truck capabilities and what makes them ideal for sensitive or compliance-driven works.

What Is Mechanical Digging?

Mechanical excavation refers to traditional digging using tracked or wheeled excavators ranging in size from compact (3T) to heavy (21T) machinery. These machines are ideal for moving large volumes of soil, rock, or pavement efficiently.

We use mechanical excavation for a wide range of tasks, including utility trenching, test pits up to 4 metres deep, bulk sampling, and access road creation. Our experienced operators carry EMI locating equipment on-site, which ensures each dig is safe, planned, and compliant with DBYD clearances.

More detail about our capabilities is outlined on our excavation services, including equipment specs and environmental sampling depth limits.

Hydro Excavation vs Mechanical Digging: Key Differences

Understanding the fundamental differences between the two methods can help match each one to your project type, budget, and risk profile. While both methods are effective, they’re suited to very different environments and needs.

| Feature | Hydro Excavation | Mechanical Digging |

| Precision | High – Ideal for utility exposure | Moderate – Designed for volume |

| Speed | Slower than mechanical | Fast for open, accessible areas |

| Environmental Impact | Low – Minimal soil disruption | Higher – More surface damage |

| Noise | Low – PTO trucks are quieter | Higher – Especially in dense areas |

| Cost | Higher upfront | Lower per cubic metre |

| Use Case | Potholing, trenching, and sensitive zones | Bulk removal, deep trenching |

| Reinstatement | Minimal required | Often requires remediation |

When Hydro Excavation Makes the Most Sense

Hydro excavation is the best fit when safety, compliance, and precision take priority over speed. This is especially true in areas where underground utilities are active and densely packed, such as CBD streets, heritage zones, or RMS roads.

Hydro is also ideal for:

- Potholing to expose live utilities

- Trenching in clay or soft ground

- Night shifts (using our quiet PTO-driven units)

- Cleaning and removing slurry or drill mud

These scenarios require non-invasive excavation techniques that minimize surface disturbance and reduce risk to both workers and existing infrastructure. Many Tier 1 contractors rely on this method to meet environmental and safety regulations on complex sites.

For example, during a rail shutdown project in Western Sydney, hydro excavation played a key role in potholing for underground services without interrupting nearby operations.

When Mechanical Digging Is the Right Choice

Mechanical excavation is still the most efficient way to remove large volumes of soil or break through dense material. It’s best used on open sites where utilities are already cleared or mapped, and space is available for machine operation.

Common use cases include:

- Bulk sample augering (up to 3m depth)

- Access road and trench creation

- De-vegetation and surface hammering

- Large test pit digging up to 4m

Our operators are certified through NULCA and BYDA, and every excavation team is equipped with electromagnetic locating gear. This means we can verify locations before cutting or digging and reduce the likelihood of strikes.

Mechanical digging is often followed by site remediation, which our crews can also handle, from subgrade compaction with rammers to hotmix or turf reinstatement with nitrogen dressing.

Can Both Methods Be Used on the Same Project?

Absolutely, and they often are. For many of our clients, a hybrid approach delivers the best results. For example, hydro excavation may be used to safely pothole around known utilities, while mechanical equipment can then trench the remaining areas where no services are present.

This staged method is:

- Safer for high-risk zones

- Faster for open-cut areas

- More cost-effective over time

Our project management team can assess your site layout and design a phased excavation strategy that integrates both techniques efficiently. This is especially helpful when your timeline is tight, but compliance still matters.

Budget, Compliance, and Environmental Considerations

Hydro excavation often has a higher daily cost, but that doesn’t mean it’s more expensive overall. By avoiding utility damage, reducing restoration needs, and complying with environmental standards, hydro excavation can offer better value in the long run.

Mechanical digging is economical on open land or rural projects, where speed and soil volume matter more than subsurface risk.

Compliance matters here, too:

- RMS road reinstatement often requires NDD

- Sensitive zones may mandate GPR + hydro

- Environmental approvals favor low-impact excavation

If you’re working in an area with strict council requirements or limited access hours, our PTO vacuum trucks and night-ready NDD crews can keep your project on track without disturbing nearby residents or infrastructure.

How We Help Clients Choose the Right Method

We don’t push one method over the other. Instead, we assess your project goals, access conditions, known utility layouts, and environmental factors to recommend the safest and most efficient approach.

It’s about doing what’s right for the site, not just what’s possible with the equipment.

From initial site assessments and utility locating to excavation, reporting, and remediation, our team provides end-to-end support. Whether you’re clearing for boreholes or laying in deep utility lines, we can tailor an excavation plan that fits your needs and reduces risk from day one.

Final Thoughts

Both hydro excavation and mechanical digging have their place. Hydro is unmatched in precision and safety, while mechanical excels in speed and scale. The key is understanding what your site demands and having a partner who can deliver both with accuracy, compliance, and care.

If you’re unsure which excavation method is right for your next project, get in touch. We’re here to guide you through the process and ensure your work proceeds safely, efficiently, and with full regulatory compliance from the ground up.