AS5488-2022 Classification of Subsurface Utility Information establishes the framework for underground utility detection across NSW construction projects. The standard defines how subsurface utilities must be identified, located, and documented to prevent service strikes and meet regulatory obligations under Work Health and Safety legislation.

What AS5488-22 Requires for Underground Utility Location in NSW

AS5488-22 mandates a four-tier classification system that determines the accuracy and reliability of underground utility data. Every utility detection activity must be assigned a Quality Level based on the investigation method used and the achieved spatial accuracy.

The standard covers all subsurface utilities, including telecommunications, electrical cables, gas pipelines, water mains, sewer lines, and stormwater infrastructure. Surface features such as pits, valve boxes, and hydrants fall within scope, while above-ground elements like overhead wires remain excluded.

Before any excavation work begins, contractors must obtain Quality Level D information through Before You Dig Australia (BYDA) searches. This desktop research provides existing utility records from asset owner,s including Ausgrid, Sydney Water, Telstra, and Jemena. While BYDA plans show approximate utility locations, they carry no spatial tolerance and serve only as preliminary information.

Field verification becomes mandatory when excavation or drilling poses a risk to existing infrastructure. Underground utility locating techniques must then be deployed to upgrade data quality from desktop records to physically verified positions.

Quality Levels Explained: QL-A, QL-B, QL-C, QL-D (When Each Applies)

Quality Level D (QL-D) represents information derived from existing records, BYDA plans, or verbal accounts from site personnel. No spatial accuracy applies. Use QL-D for initial feasibility studies and preliminary site assessments where excavation is not imminent.

Quality Level C (QL-C) involves a professional survey of visible surface features such as manholes, valve boxes, and access pits. The surveyed points are recorded with coordinate data, but the underground utility route between features remains interpolated. Apply QL-C when surface infrastructure is accessible, and mapping surface assets supports design development.

Quality Level B (QL-B) requires geophysical detection using electromagnetic locators or ground penetrating radar to identify subsurface utility positions. Horizontal accuracy reaches ±300mm and vertical accuracy ±500mm. All QL-B detections must include metadata documenting the detection method, equipment used, date of survey, and operator qualifications.

QL-B suits most excavation projects where utilities must be marked before digging begins. Construction activities, including trenching, test pitting, and borehole drilling, typically specify QL-B as the minimum acceptable standard.

Quality Level A (QL-A) delivers the highest accuracy through physical exposure of utilities via non-destructive digging methods. Once exposed, utilities are surveyed to ±50mm horizontal and vertical tolerance. The exposed section reveals exact depth, diameter, material, condition, and configuration.

QL-A becomes essential for high-risk activities near critical infrastructure, validation of uncertain QL-B detections, works-as-executed documentation, and projects requiring millimeter-precision utility data for clash detection with proposed structures.

Documentation Requirements: What Must Be Recorded During Utility Detection

AS5488-22 specifies mandatory documentation elements for each Quality Level. Every utility detection report must state the Quality Level achieved using the standardized acronym: QL-A, QL-B, QL-C, or QL-D.

For QL-B detections, operators must record the specific geophysical method employed. Electromagnetic induction locating requires documentation of signal frequency, transmission mode (direct connection, induction, or passive), and whether the utility carried active signal. Ground penetrating radar surveys must note antenna frequency, soil conditions affecting penetration, and any limitations encountered.

The detection date and time capture when the investigation occurred. This temporal data proves critical for projects spanning multiple months where site conditions may change between investigation phases.

Spatial data varies by Quality Level. QL-D carries no coordinate requirement. QL-C records surveyed coordinates of surface features only. QL-B documents the detected utility path with coordinates at key points along its route. QL-A provides fully surveyed 3D coordinates of the exposed utility section.

Utility attributes, including type (water, gas, electrical, telecommunications), material (PVC, copper, steel, concrete), diameter or cable count, and ownership, must be recorded where determinable. For QL-A exposures, condition assessment noting corrosion, damage, or deterioratio,n adds value to the dataset.

Utility reporting and mapping deliverables range from marked-up site photos for simple projects to CAD drawings and GIS datasets for major infrastructure developments.

Verification Methods Required by AS5488-22 (NDD Potholing Standards)

AS5488-22 defines vacuum excavation as the preferred method for achieving Quality Level A verification. Non-destructive digging prevents damage to utilities during exposure while providing visual confirmation of position, depth, and attributes.

Potholing must extend to sufficient depth to fully expose the target utility. Where utilities stack vertically, excavation continues until all services within the investigation area are revealed and surveyed. Minimum pothole dimensions allow clear photography and measurement of exposed utilities.

The standard requires independent verification when QL-B detections show uncertainty or when conflicting data exists between BYDA plans and field detection results. Utilities marked as “approximate” on asset owner plans warrant QL-A verification before excavation proceeds within two meters of the indicated position.

High-risk scenarios mandating QL-A verification include work within five meters of high-voltage electrical infrastructure, proximity to gas transmission pipelines operating above 1050 kPa, excavation deeper than four meters where utilities may be stacked, and any location where previous utility strikes have occurred.

Post-verification survey captures precise coordinates using total station or GPS equipment calibrated to the project datum. Survey reports link to the originating QL-B detection data, creating a traceable verification chain.

How AS5488-22 Integrates with WHS Regulation 2017 for NSW Projects

Work Health and Safety Regulation 2017 places a duty of care on persons conducting a business or undertaking (PCBUs) to identify hazards and manage risks. Underground utilities represent a significant hazard category where AS5488-22 provides the technical methodology to satisfy WHS obligations.

SafeWork NSW codes of practice reference AS5488-22 as the recognized standard for subsurface utility investigation. Compliance with the standard demonstrates reasonable steps have been taken to identify and manage underground service strike risks.

Safe Work Method Statements (SWMS) for excavation activities must reference the Quality Level of utility data being relied upon. Using only QL-D information for excavation near known utilities fails to meet WHS risk management requirements. The SWMS must specify that QL-B detection or QL-A verification has been completed before excavation commences.

When utilities are struck despite following AS5488-22 procedures, the documented investigation process provides evidence that reasonable precautions were implemented. Conversely, utility strikes occurring without proper investigation expose PCBUs to prosecution under WHS legislation.

Incident notification requirements under WHS Regulation 2017 apply when utility strikes cause service interruption, pose immediate danger to persons, or result in injury. AS5488-22 compliance reduces strike probability, thereby minimizing regulatory incident reporting obligations.

Common AS5488-22 Compliance Failures (5 Mistakes Contractors Make)

Relying solely on BYDA plans without field verification. Desktop data alone does not satisfy AS5488-22 requirements for excavation work. Many contractors proceed with digging based only on QL-D information, later discovering utilities in unexpected positions.

Assigning incorrect Quality Levels to investigation work. Electromagnetic locating performed without proper metadata documentation cannot be classified as QL-B. Similarly, exposing utilities without a survey does not achieve QL-A. Quality Level inflation creates false confidence in data accuracy.

Failing to document detection methods and equipment. QL-B reports lack details about whether electromagnetic induction or ground penetrating radar was used provide incomplete information. Subsequent users cannot assess data reliability or determine where additional verification is needed.

Inadequate verification of uncertain detections. When electromagnetic locators receive ambiguous signals or GPR scans show multiple reflections, contractors sometimes mark estimated positions rather than conducting vacuum excavation to confirm the actual utility location.

Neglecting to update Quality Levels as projects progress. Initial QL-B detections should be upgraded to QL-A when utilities are subsequently exposed during construction. Failing to survey and document exposed utilities wastes opportunities to improve the overall dataset quality for future project phases and asset owner records.

How Smartscan Ensures AS5488-22 Compliance on Every Project

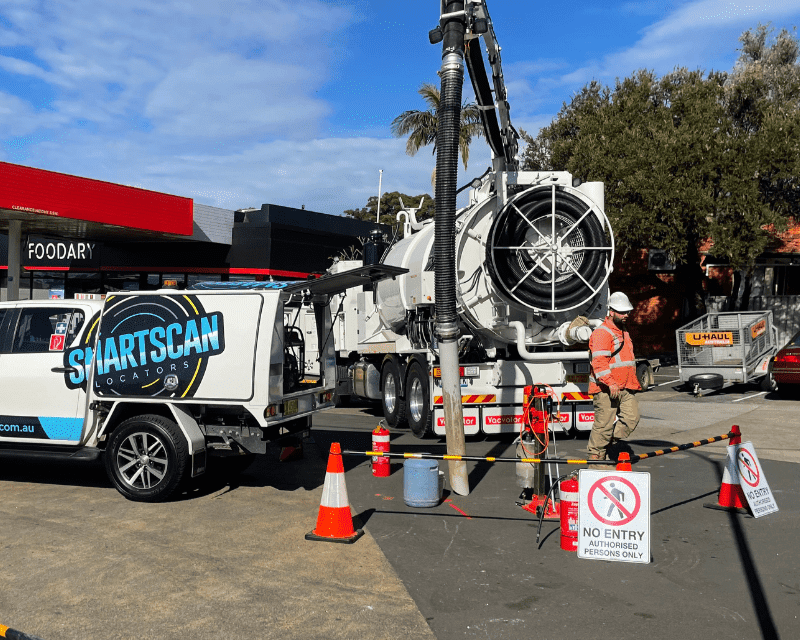

Smartscan Locators maintains AS5488-22 compliance through systematic investigation protocols that match Quality Level requirements to project risk profiles. Our BYDA Certified locators and Telstra Accredited Plant Locators bring over 140 combined years of experience applying the standard across NSW construction sites.

Equipment capabilities span all detection methods required by AS5488-22. Radiodetection RD8000 and Vivax Vloc3 electromagnetic locators provide QL-B detection for metallic utilities. Mala and Leica ground penetrating radar systems map non-metallic services, including PVC water mains and concrete stormwater pipes.

Non-destructive digging vacuum trucks deliver QL-A verification through potholing, with dual gerni units accelerating excavation to meet tight project schedules. Survey equipment captures exposed utility coordinates to ±50mm tolerance.

Documentation standards exceed AS5488-22 minimum requirements. Reports include detection method details, equipment specifications, operator qualifications (RIICCM202D certification), site conditions, and limitations encountered. Online accessible storage drives maintain organized records throughout multi-stage projects.

Quality assurance processes verify that assigned Quality Levels accurately reflect investigation methods and achieved accuracy. Before reports are issued, technical reviewers confirm that all metadata elements are present and that the spatial data meet tolerance specifications.

For projects requiring multiple investigation phases, Smartscan coordinates the progression from QL-D desktop research through QL-B detection to QL-A verification, ensuring each phase builds upon previous data while maintaining compliance documentation throughout the project lifecycle.

Contact Smartscan Locators at 1300 778 923 or [email protected] to discuss an AS5488-22 compliant utility investigation for your NSW project.