Electromagnetic induction locators detect metallic underground utilities by transmitting electromagnetic signals that induce current in conductive pipes and cables, which receivers then trace to determine location, depth, and path. Ground penetrating radar systems emit high-frequency radio pulses into the ground and measure reflection patterns from subsurface materials, detecting both metallic and non-metallic utilities based on dielectric contrast between materials.

Sydney’s varied geology creates distinct detection challenges, with Western Sydney’s Wianamatta Shale clay limiting GPR penetration to 1.5-2.5m while maintaining EMI effectiveness to 6-8m, whereas Northern Beaches Hawkesbury sandstone allows GPR penetration to 3-5m with both methods performing optimally.

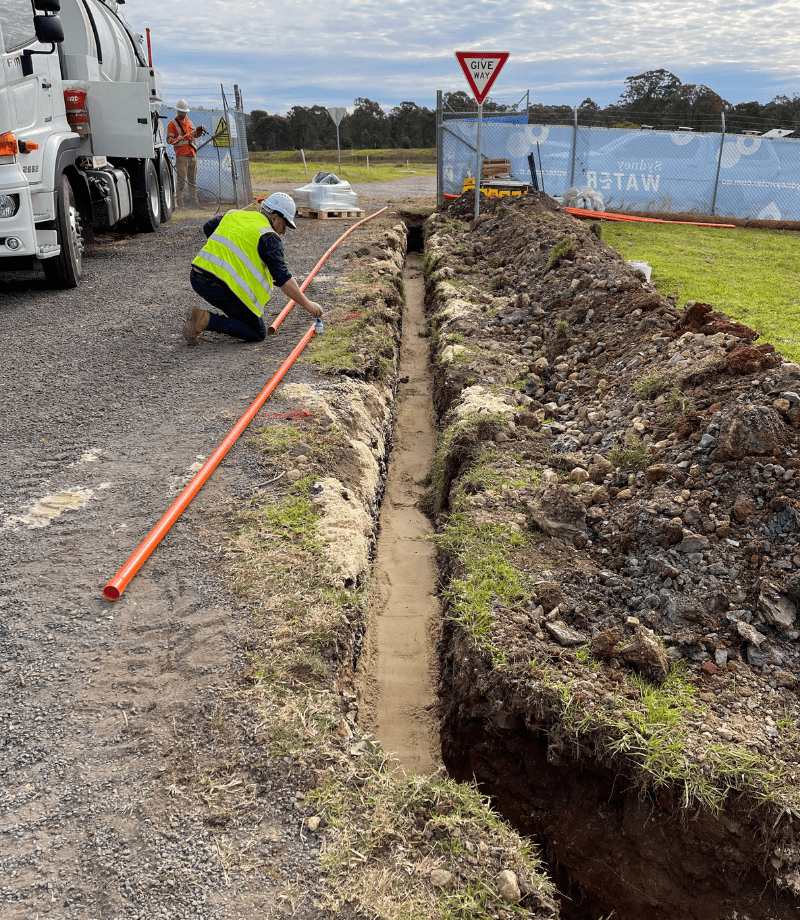

Complex infrastructure projects achieve 99.8% utility detection accuracy by combining electromagnetic locators for metallic utility tracing with ground penetrating radar for non-metallic detection, followed by selective vacuum excavation for physical verification.

How Electromagnetic Induction (EMI) Locators Detect Underground Utilities

Electromagnetic induction locators detect underground utilities through three operating modes, each suited to different site conditions. Direct connection mode provides the highest accuracy by physically connecting the transmitter to the utility via access points, tracer wires, or valve boxes, generating a strong electromagnetic field that receivers trace to 8m depth in optimal NSW soil conditions.

Induction mode places the transmitter on the ground surface, broadcasting electromagnetic signals that induce current onto nearby conductive utilities without physical connection, effective for rapid site surveys, though with reduced accuracy and depth capability. Passive mode detects electromagnetic fields already present on energized power cables or radio frequencies radiating from telecommunications infrastructure, useful for initial site reconnaissance.

Smartscan technicians use Radiodetection RD8000 and Vivax Vloc3 electromagnetic locators across Greater Sydney, selecting operating mode based on utility access availability and project accuracy requirements.

Direct connection achieves ±100mm horizontal accuracy for metallic water mains, gas lines, and electrical cables, while induction mode provides ±300mm accuracy suitable for preliminary mapping. EMI locators excel at tracing long utility runs, detecting services in wet clay soils where GPR signals attenuate, and rapid project timelines requiring real-time results.

How Ground Penetrating Radar (GPR) Maps Subsurface Infrastructure

Ground penetrating radar technology uses electromagnetic pulse transmission to map subsurface features through dielectric contrast detection. High-frequency antennas (500-700MHz) provide 2-3cm vertical resolution for shallow utilities and concrete scanning applications, penetrating 2-3m depth. Low-frequency antennas (250MHz) sacrifice resolution for deeper penetration, achieving 4-5m depth in Hawkesbury sandstone and coastal sandy soils prevalent across Northern Beaches and Eastern Suburbs.

GPR systems generate radargrams, visual cross-sections showing subsurface anomalies as hyperbolic reflections (point objects like pipes), horizontal layers (soil strata changes), or chaotic patterns (reinforced concrete).

Smartscan operates Mala and Leica GPR units, selecting antenna frequency based on detection depth requirements and expected utility size. GPR detects PVC stormwater pipes, HDPE conduits, concrete structures, fiber optic cables, and voids that electromagnetic locators cannot identify, making it essential for comprehensive subsurface mapping on sites without complete utility plans.

When EMI Locators Outperform GPR in Sydney Projects

Electromagnetic locators prove most effective in five specific scenarios common across NSW infrastructure projects. Long-distance metallic utility tracing requires EMI’s ability to follow continuous electromagnetic signals along gas mains, water mains, and electrical cables extending hundreds of meters, where GPR’s line-by-line scanning becomes time-prohibitive and cost-ineffective.

Western Sydney’s Wianamatta Shale clay geology, prevalent across Campbelltown, Liverpool, Penrith, and Blacktown, creates high soil conductivity that severely attenuates GPR signals to 1.5-2.5m penetration while EMI locators maintain 6-8m metallic utility detection depth. Deep utility detection beyond 4m depth favors EMI methodology, particularly for trunk water and sewer mains installed 5-8m below major roads and highways.

Projects with known metallic utilities and available access points benefit from direct connection EMI, achieving survey-grade accuracy without GPR’s higher equipment and interpretation costs. Rapid site assessments requiring same-day results leverage EMI’s real-time detection capability, providing immediate utility markup for excavation crews versus GPR’s data processing and analysis timeframes.

When GPR is Essential for NSW Utility Detection

Ground penetrating radar becomes mandatory for six critical use cases where electromagnetic locators cannot provide adequate subsurface information. Non-metallic utility detection represents GPR’s primary advantage, PVC stormwater systems, HDPE gas conduits, concrete sewer pipes, and fiber optic cables contain no conductive materials for EMI signals to trace, requiring radar pulse reflection detection.

Concrete scanning before coring, drilling, or saw-cutting prevents catastrophic post-tension cable strikes that cause structural failure and $50,000+ repair costs. GPR identifies rebar layouts, embedded conduits, and tensioned cable locations within slabs, walls, and bridge decks before invasive work begins.

Sites without utility plans or BYDA records require GPR’s comprehensive subsurface imaging to reveal unknown services, abandoned infrastructure, and unmarked installations that pose excavation strike risks. Sydney CBD and congested infrastructure corridors contain overlapping utilities from multiple asset holders, Ausgrid electrical, Sydney Water pipes, Telstra telecommunications, NBN fiber, where GPR maps the complete subsurface profile versus EMI’s selective metallic detection.

AS5488-22 Quality Level A projects requiring ±100mm accuracy with physical verification use GPR to guide non-destructive digging potholing locations, reducing excavation volume by 40% while meeting exposure confirmation requirements.

Northern Beaches, Eastern Suburbs, and Upper North Shore sandy soils provide optimal GPR penetration to 3-5m depth, maximizing detection capability where geological conditions favor radar technology.

Rouse Hill Water Recycling Plant expansion (2023) demonstrates GPR necessity; EMI-only methodology detected metallic water and electrical services, but missed 47m of PVC stormwater network. Discovery during excavation caused a 3-day project delay and $12,000 remediation cost for emergency utility relocation and site reinstatement.

Soil Conductivity Impact on Detection Method Performance Across Sydney

Sydney’s geological diversity directly determines the detection method across the suburbs. Wianamatta Shale clay, underlying Western Sydney from Campbelltown through Liverpool to Penrith, contains high moisture retention and conductive minerals that absorb GPR signals, limiting penetration to 1.5-2.5m depth. EMI locators maintain 6-8m metallic utility detection in these conditions, making electromagnetic methodology preferred for Western Sydney projects unless non-metallic utilities require investigation.

Hawkesbury sandstone, forming the bedrock across Northern Beaches (Manly, Mona Vale), Upper North Shore (Hornsby, Turramurra), and parts of Inner West, provides low-conductivity conditions optimal for both detection methods. GPR achieves 3-5m penetration depth with clear radargram imaging, while EMI locators reach a maximum 8m capability for deep metallic services.

Coastal sandy soils throughout Eastern Suburbs (Bondi, Coogee, Maroubra) and beachside Northern Beaches offer ideal GPR performance with minimal signal attenuation. Both methods operate at peak capability in these geological formations.

Seasonal moisture variation affects detection performance; wet winter months (June-August) reduce GPR penetration 20-30% as saturated soils increase conductivity, while dry summer conditions (December-February) provide optimal detection across all soil types.

Cost-Benefit Analysis: Detection Method Investment vs Strike Risk

EMI-only utility investigations cost $450-$650 per site across NSW, suitable for projects where utilities are predominantly metallic, BYDA plans indicate comprehensive records, and soil conditions favor electromagnetic detection. GPR-only surveys cost $800-$1,200 per site when non-metallic utility detection drives requirements or concrete scanning applications necessitate radar technology.

Combined EMI and GPR methodology costs $1,100-$1,600 per site, deploying both technologies to achieve 99.8% detection accuracy on complex sites with mixed utility types, unknown services, or congested infrastructure corridors. Smartscan’s 1,200+ projects since 2015 demonstrate this investment prevents average $8,500-$15,000 utility strike costs comprising:

Direct damage repair to struck utilities averages $3,500-$6,000, depending on service type; gas line repairs exceed electrical cable fixes due to emergency response requirements and regulatory notifications. Project delay costs range from $2,000 to $5,000 for equipment standing time, crew redeployment, and schedule compression to recover lost days. Emergency callout fees, traffic management, and utility asset holder attendance add $1,500-$3,000 to strike incidents. Site remediation and surface reinstatement following utility repairs cost $1,500-$4,000 for excavation backfill, compaction, and pavement restoration.

Single utility strike avoided funds 5-10 combined detection investigations, demonstrating clear return on comprehensive methodology for medium to high-risk projects. Small residential renovations with simple utility configurations may justify an EMI-only approach, while commercial developments, infrastructure projects, and unknown utility scenarios demand combined detection to mitigate strike probability.

How Smartscan Locators Determines Optimal Detection Method

Smartscan applies a six-factor decision framework to select utility detection methodology for each NSW project. Site soil assessment begins with electromagnetic conductivity testing and geological formation identification—Wianamatta Shale geology indicates EMI preference for metallic utilities and GPR limitations, while Hawkesbury sandstone or coastal sands support full GPR capability.

Utility-type probability assessment analyzes BYDA plans, project-type indicators, and historical utility presence patterns. Residential properties typically contain metallic water, gas, and electrical services suited to EMI detection, while commercial sites add PVC stormwater, fiber optic telecommunications, and concrete structures requiring GPR investigation.

Depth requirements influence method selection, utilities within 2m depth suit both technologies, 2-4m range depends on soil and utility type, and services beyond 4m depth favor EMI for metallic materials or necessitate alternative investigation methods. AS5488-22 Quality Level specifications drive detection accuracy and verification requirements. Quality Level B accepts electromagnetic location with survey positioning, while Quality Level A demands GPR guidance for physical exposure through vacuum excavation.

Site complexity evaluation distinguishes single utility trace scenarios where EMI provides cost-effective results from congested corridors requiring comprehensive GPR mapping. Budget and timeline constraints balance investigation costs against utility strike risk, with compressed schedules sometimes necessitating faster EMI methodology despite reduced coverage.

Smartscan’s NULCA-certified technicians carry Radiodetection RD8000 electromagnetic locators, Vivax Vloc3 backup systems, Mala GPR 250MHz antennas for broad subsurface imaging, and Leica GPR 500MHz antennas for high-resolution shallow detection. Equipment diversity enables on-site methodology adjustment when initial detection results prove inconclusive or when site conditions differ from desktop assessment expectations. Contact Smartscan’s consultancy team for project-specific detection methodology selection: 1300 778 923 or [email protected].

Frequently Asked Questions

How deep can electromagnetic locators detect underground utilities in Sydney soil?

Electromagnetic locators detect metallic utilities to 6-8m depth in Sydney’s low-conductivity sandy soils (Northern Beaches, Eastern Suburbs) and 4-6m in Wianamatta Shale clay (Western Sydney). Detection depth decreases in saturated conditions and when using induction mode rather than direct connection.

Can ground penetrating radar detect PVC pipes?

Ground penetrating radar detects PVC pipes, HDPE conduits, and all non-metallic utilities through dielectric contrast measurement. GPR penetration depth ranges from 1.5-2.5m in Sydney clay soils to 3-5m in sandy coastal areas.

What is the most accurate method for locating underground utilities?

Combined electromagnetic locating and ground penetrating radar methodology achieves 99.8% detection accuracy. Physical verification through vacuum excavation provides 100% confirmation and meets AS5488-22 Quality Level A requirements.

How much does combined EMI and GPR detection cost?

Combined electromagnetic and GPR investigation costs $1,100-$1,600 per site in NSW, preventing average $8,500-$15,000 utility strike costs, including excavation delays, repair expenses, and project remediation.