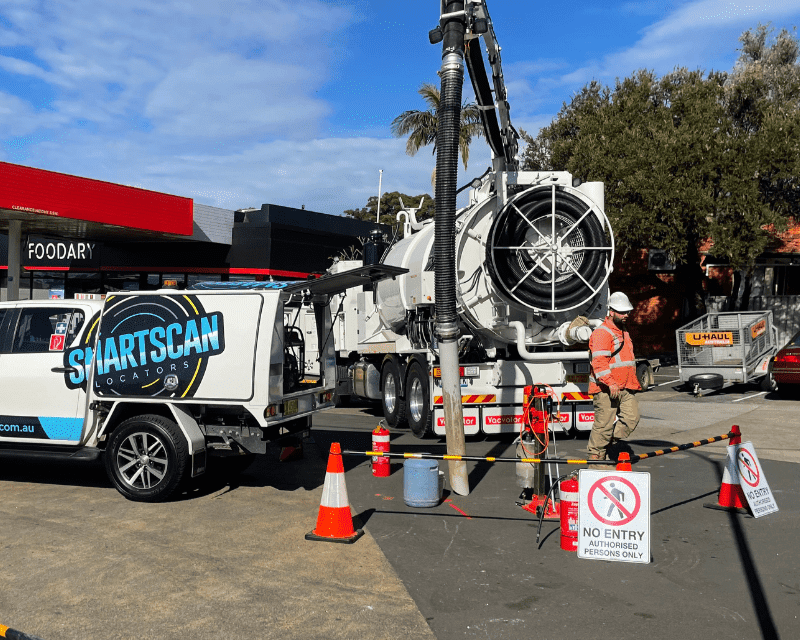

Non-Destructive Digging (NDD) is a precision excavation method that uses pressurised water or air and vacuum extraction to safely expose underground utilities without damage. In New South Wales, it is widely adopted in urban, rail, and environmentally sensitive areas, where even minor utility strikes can cause costly delays and safety risks.

By gently removing soil without disturbing telecommunications, electrical cables, water pipes, or gas lines, NDD has become the standard for projects that demand accuracy, compliance, and minimal environmental impact.

What is Non-Destructive Digging in NSW?

Non-Destructive Digging (NDD) is a precision excavation method that uses high-pressure water or air and vacuum extraction to safely expose underground utilities without damage. In NSW, it’s widely adopted in urban, rail, and environmentally sensitive zones, reducing utility strikes and minimising environmental disturbance.

Key Use Cases: Utility locating, potholing, environmental sampling, pipeline installation, often paired with Ground Penetrating Radar (GPR) for exact asset verification.

Why is NDD the Safest Excavation Method in NSW?

Non-Destructive Digging (NDD) is preferred in NSW for its unmatched safety record. By using water or air to gently uncover underground utilities, NDD reduces utility strike incidents, protects workers, and preserves the environment, making it the method of choice in metro, rail, and heritage areas.

Safety Advantages:

- Minimised Utility Strikes – Prevents costly damage to power, water, sewer, and telecom lines.

- Worker Safety – Reduces the risk of injury by avoiding heavy machinery near live assets.

- Environmental Protection – Low dust, low vibration excavation for sensitive zones.

- Certified Operators – BYDA, Telstra Accredited Plant Locator, and NULCA trained teams ensure compliance.

How Non-Destructive Digging Works in NSW

The NDD process is a structured 5-step method designed to expose underground utilities without damage. Using advanced locating tools, water or air, and vacuum extraction, this approach delivers clean, compliant excavations while keeping a full audit trail.

5 Key Steps:

- Service Location & Marking – Use electromagnetic locators and GPR to map utilities, marked to AS5488 standards.

- Soil Loosening – Apply water or air via specialised lances to gently break up soil.

- Vacuum Extraction – Remove loosened material with high-powered suction into a debris tank.

- Inspection & Verification – Record measurements and photographic evidence for reports.

- Backfilling & Remediation – Restore site with RMS-compliant materials and compaction methods.

Where NDD is Used in NSW

Non-Destructive Digging’s precision and safety make it ideal for a range of NSW projects, from city infrastructure to environmental work. Its ability to expose assets without damage saves time, money, and compliance headaches.

Common Applications:

- Utility Potholing – Confirm asset depth and location before building.

- Pipeline Installation – Provide safe trench access for water, gas, and sewer lines.

- Rail & Road Works – Excavate in high-voltage or high-traffic zones without service disruption.

- Environmental Sampling – Extract clean soil for testing and contamination analysis.

- Drainage & Stormwater – Work around live pipes and drains without damage.

When combined with utility mapping and reporting, NDD speeds up design approvals and reduces rework costs by up to 30%.

NDD vs Mechanical Digging — Which is Better?

For NSW projects where underground utilities are present, Non-Destructive Digging offers higher precision, lower risk, and minimal environmental impact compared to traditional mechanical digging. Mechanical methods remain faster for bulk earthworks but carry a higher chance of asset strikes.

Comparison Table:

| Aspect | NDD | Mechanical Digging |

| Precision | Isolates utilities without disturbing the surroundings | Can disturb nearby assets |

| Risk Level | Low – controlled around utilities | Higher chance of strikes |

| Environmental Impact | Minimal dust & displacement | Greater disturbance |

| Speed | Ideal for targeted work | Faster for large open areas |

Best Practice: Combine both, use mechanical digging for open excavation and NDD for utility-rich or sensitive areas.

NDD Compliance Standards in NSW

Every Non-Destructive Digging project in NSW must follow strict safety and legislative frameworks. Compliance protects underground assets, avoids costly fines, and speeds up project approvals.

Key Standards:

- AS5488 – Classifies subsurface utility data for consistent recording and reporting.

- BYDA Protocols – Ensures work complies with “Before You Dig” asset protection standards.

- NULCA Guidelines – Sets the benchmark for professional locating and verification.

By integrating these requirements into every project, our NDD teams achieve 100% compliance rates, earning trust from councils, utility providers, and Tier 1 contractors.

Operational Advantages of NDD

Non-Destructive Digging delivers more than just safety. It improves site efficiency, minimises disruption, and adapts to complex conditions, making it a preferred method for NSW infrastructure projects.

Key Benefits:

- Less Site Disruption – Compact work zones keep businesses and traffic flowing.

- Cleaner Work Environment – Contained debris means less post-job cleanup.

- Night & Sensitive Works – Low-noise PTO-driven trucks suit CBD and restricted-hour projects.

- Adaptability – Performs in mixed soil types, including clay, without damaging assets.

These advantages have made NDD the chosen excavation method for Tier 1 contractors, councils, and private developers across NSW.

How NDD Integrates with Other Services

In NSW infrastructure projects, Non-Destructive Digging delivers its best results when combined with complementary subsurface investigation methods. This integration improves accuracy, documentation, and reinstatement quality.

Common Service Combinations:

- NDD + Ground Penetrating Radar – Enhances accuracy when locating non-conductive assets.

- NDD + Utility Mapping & Reporting – Creates detailed records for maintenance and compliance.

- NDD + Remediation Services – Ensures reinstatement meets or exceeds RMS standards.

This holistic approach delivers projects with zero asset strikes, full compliance, and clear documentation, ready for audits or future works.

When NDD is the Right Choice in NSW

Non-destructive digging is ideal for projects where underground asset safety, precision, and environmental compliance are critical. If your site conditions match any of the following, NDD is the recommended approach:

- Congested Utility Corridors – Prevent strikes in crowded underground networks.

- High-Value or Sensitive Assets – Protect infrastructure like fibre optics or gas lines.

- Strict Compliance Requirements – Meet NSW safety and legislative standards.

- Environmental Sensitivity – Minimise dust, vibration, and soil disruption.

- Restricted Access Sites – Achieve pinpoint excavation in tight spaces.

For large-scale open areas, mechanical digging may be faster, but combining both methods can deliver maximum safety, speed, and cost-efficiency.

Moving Forward with NDD in NSW

In NSW, Non-Destructive Digging is more than a safe excavation method. It’s a proven risk management tool. By carefully exposing underground assets, NDD prevents service outages, protects workers, and meets strict environmental regulations.

Whether your project is in design, construction, or maintenance, integrating NDD can cut delays, reduce repair costs, and safeguard compliance.

Next Step: Contact our team for a free project assessment, explore our vacuum truck services, or learn more about utility locating to ensure your site is ready before breaking ground.

Frequently Asked Questions About NDD in NSW

What is the difference between NDD and hydro excavation?

They’re essentially the same process. Hydro excavation is another term for NDD, where pressurised water loosens soil before vacuum extraction.

Is NDD safer than mechanical digging in NSW?

Yes. NDD minimises utility strikes, vibration, and dust, making it the safer choice in congested or sensitive areas.

How much does NDD cost per metre in NSW?

Costs vary based on site access, soil type, and project size, but NDD is often more cost-effective when factoring in reduced rework and repair costs.

What certifications are required for NDD operators?

In NSW, operators should hold BYDA, Telstra Accredited Plant Locator, and NULCA certifications for compliance and safety.

Can NDD be used in clay or rocky soils?

Yes. NDD equipment can work in mixed soil conditions, including clay, without damaging underground assets.